Tripolar electromagnets with moving poles, adaptable to the load, are the new patent of FELEMMAG in the field of magnetic lifting and electromagnetic systems.

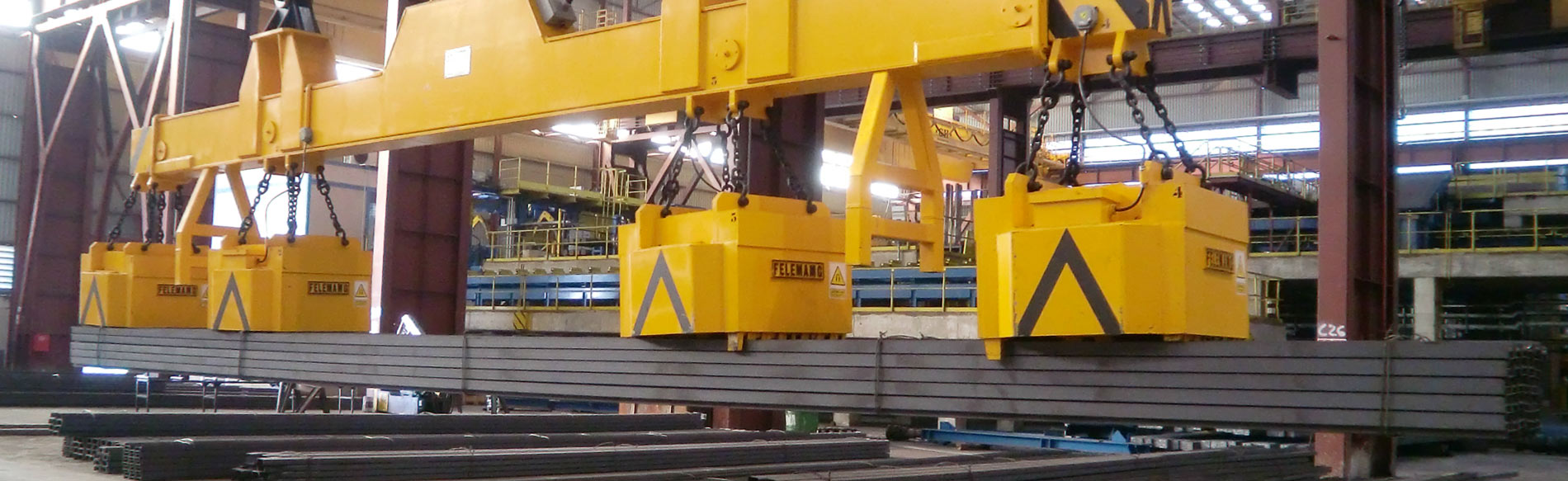

These are a large section and depth-field electromagnets, whose main characteristic is its great capacity to adapt perfectly to the surface of the load to lift. This characteristic makes them undoubtedly the best option for handling loads with non-flat surfaces such as laminated profiles, tubes, round bars, etc. They are particularly suitable for steel storage depots and warehouses that store this type of material.

The lifing of these type of loads, has the difficulty of having a small contact area between the load and the magnetic poles, which limits the magnetic strength that the magnet is able to perform over those loads. Therefore, it is required the utilization of large coils or permanent magnets to provide enough force to overcome the large air gap between the poles of the electromagnet and the load.

Using the tripolar electromagnets with moving poles, patented by FELEMAMG, this problem disappears. The mobility of the magnetic poles allows to adapt to the surface to the load, thereby increasing significantly the contact area and being each one of the poles useful for the lifting of the load.